AWC Water Solutions

AWC Water Solutions Ltd. designs and builds complete packaged and modular water and wastewater treatment systems. AWC Water Solutions has one of the most experienced groups of water and wastewater treatment experts in the industry. The team has decades of history in designing and successfully delivering one of the most widely recognized water treatment systems in the industry. Their in-house engineering and technical team, together with optional pilot studies, will work with you to select the best process and design a custom package to reliably meet environmental, financial and quality standards for your project. Depending on your needs, AWC will help you select a new plant or retrofit your current system.

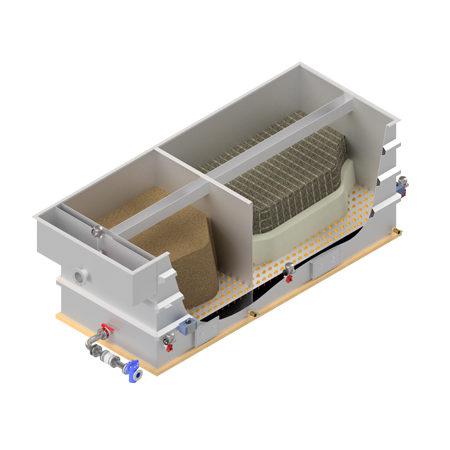

AC Clarifier

AC plants are ideally suited for stable ground or surface waters where turbidity levels seldom exceed 30 NTU.

AWC AC plants are custom designed to meet our clients’ needs. They use a combination of hydraulic “tortuous path” flocculation/clarification filtration and rapid rate filtration to produce potable water with superior quality. The AC Clarifier plant can treat capacities up to 2,800 gpm (2 MGD) per train (multiple trains can be combined for higher flows). They also reliably achieve less than 0.1 NTU turbidity and 2.5-log, multi-barrier protection against Giardia and Cryptosporidium.

Contact Us

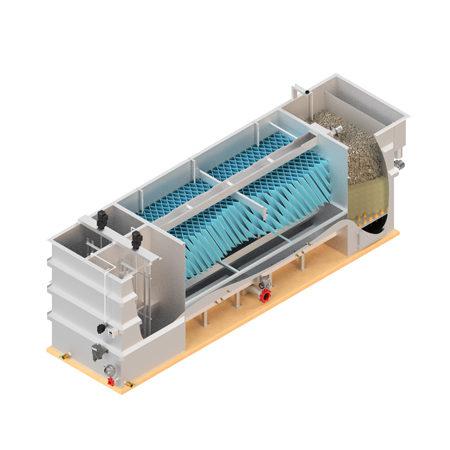

Tube Settler

ST plants use proven technologies to produce clear, safe drinking water from low quality sources. Capable of purifying the most difficult types of raw water, our ST plants are particularly suited for surface waters with high and variable contaminant loAWCngs and excel in treating cold water and very high levels of turbidity, iron and manganese.

AWC ST plants are custom designed to meet our clients’ needs. They can treat capacities up to 800 gpm (4,400 m3/d) per train (multiple trains can be combined for higher flows) and reliably achieve less than 0.1 NTU turbidity and 2.5-log, multi-barrier protection against Giardia and Cryptosporidium.

Contact Us

Dissolved Air Flotation (DAF)

DAF plants excel in treating lake and reservoir water containing high levels of color, algae and turbidity, as well as cold waters and high levels of iron and manganese.

AWC DAF plants are custom designed to meet our clients’ particular challenges. They can treat capacities up to 1,400 gpm (7,600 m3/d) per train (multiple trains can be combined for higher flows) and reliably achieve less than 0.1 NTU turbidity and 2.5-log, multi-barrier protection against Giardia and Cryptosporidium.

Contact Us

Direct Filtration (DF)

The DF plants use a combination of hydraulic or mechanical flocculation and rapid rate filtration to provide superior quality to potable water. They are ideal for stable ground or surface waters where turbidity levels seldom exceed 10 NTU.

Our DF plants are custom designed to meet our clients’ needs. They can treat capacities up to 1,500 gpm (8,100 m3/d) per train (multiple trains can be combined for higher flows) and reliably achieve less than 0.1 NTU turbidity and 2-log protection against Giardia and Cryptosporidium.

Contact Us

Ultra and Nano Membrane Filtration and Reverse Osmosis

AWC Water Solutions is in a strategic partnership with Hydranautics for Ultrafiltration (UF) membrane technology and Nanofiltration (NF) / Reverse Osmosis (RO) applications.

Hydranautics is a leader in the field of Membrane Filtration.

AWC Water Solutions builds the systems including controls & ancillaries and employs the respective filter module cartridges.

Contact Us

Pressure Filters

In the filtration process, large particulate matter is captured by coarser, lighter media near the top of the filter bed. Smaller particles continue down to the successive lower media levels, where the spaces between these finer media capture the particles down to 10 microns.

This multi-media filter allows a pressure drop build up across each media section, thereby utilizing the full bed depth for filtration of all particle sizes.

Contact Us

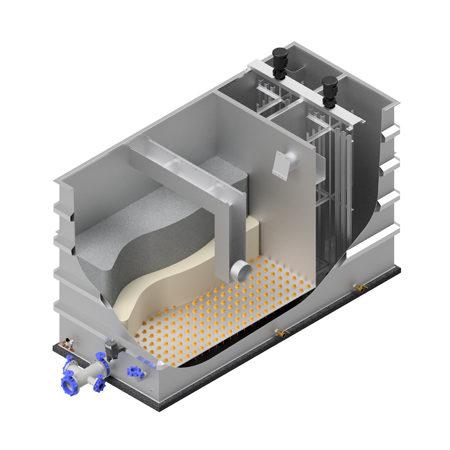

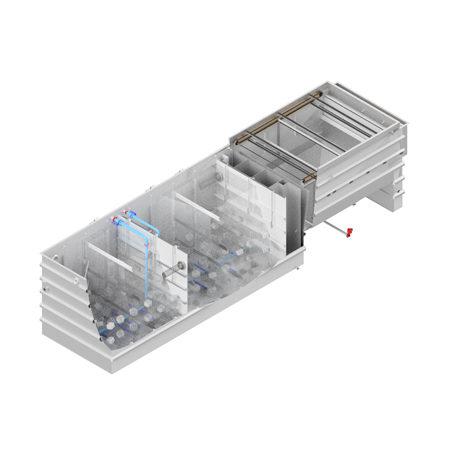

Moving Bed Bioreactor (MBBR)

AWC packaged MBBR plants are pre-assembled and pre-tested in our controlled facility, often saving 50 percent or more over in-situ construction.

The MBBR plants are uncomplicated and easy to operate. Also, the use of MBBR media greatly reduces the main reactor footprint.

Contact Us

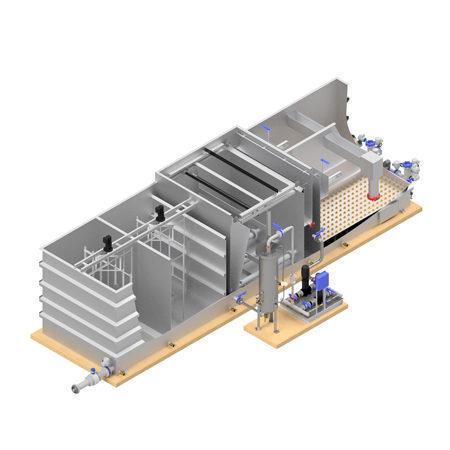

Membrane Bioreactor (MBR)

AWC Water Solutions offers packaged membrane bioreactor (MBR) wastewater treatment plants based on submerged membrane modules.

Designed to treat domestic, commercial and industrial sewage for the removal of biochemical oxygen demand, total suspended solids, total nitrogen, ammonia and phosphorous, the AWC MBR plant achieves very high re-use quality water and can handle a wide variation in loading and flow rates. Automation and flexible operating parameters deliver a cost-effective, trouble-free treatment process.

Contact Us