Cornell

Cornell Pump Company manufactures pumps for a wide variety of markets, addressing some of the most challenging of applications. Initially offering solutions for the agriculture market, Cornell’s 70+ year history has made it the premier choice for some of the most demanding conditions imaginable. From sugar fields, to mines, to wastewater stations, the pumping requirements may change, but the basic Cornell values stay the same: unmatched performance, robust design, global support and an in depth understanding of our customers’ needs.

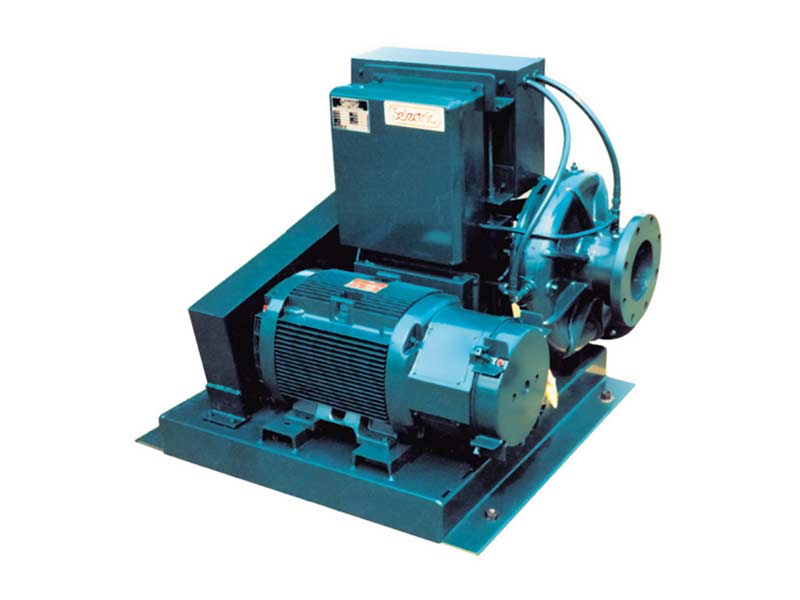

Clear Liquid Pumps

Cornell’s Clear Liquid pumps are known around the world as the most durable, most reliable, highest efficiency pumps in the industry. They can be found in a variety of applications in the Agricultural, Industrial, and Municipal markets and are available in Close-Coupled, SAE Engine Mounted, Horizontal, and Vertical Configurations.

Learn More

Cutter Pumps

The cutter pump was created to address the urgent need to reduce clogging due to ragging. With the increased use of ‘flushable’ materials and extraneous cleaning products, the issue of clogging, which leads to downtime, pump destruction, and pipe damage, has increased markedly. Useful in municipal, agricultural, and other markets, the cutters unique stationary and rotating blade design allows material to pass through the impeller that would tend to clog a non-cutter pump. The cutter costs a minimal amount of product efficiency and is specially designed to break up clogs and prevent ragging. The cutter is adjustable and made from special hardened metal to last in difficult service. The cutter impeller can be retrofitted on existing pumps, and won’t change the external pump dimensions.

Learn More

Hydro-Transport Pumps

Cornell introduced the first Hydro-Transport food process pump to the industry almost 40 years ago, and has maintained its reputation ever since with pumps that can transport a wide range of food items – from potatoes to tomatoes – with minimal damage.

In addition to the P and PP series pumps, many other Cornell pumps are used in the food industry for applications such as waste water, hot oil, and clear liquids.

Learn More

Hot Oil Pumps

Cornell’s Hot Oil pumps offer enhanced vapor handling to prevent entrained steam from impacting pump head and flow. When fresh product passes through the fryers a great deal of water is released. The water travels along the bottom of the fryer, intact in a liquid phase at 200°C, until it reaches the pump suction. Here the action of the impeller breaks up the water into smaller droplets which flash to steam. Ordinarily, this entrained steam would severely impact pump head and flow, but this impact is mitigated by Cornell’s innovative vapor suppression line.

Learn More

Hydroturbines

Cornell has been building Hydro Turbines for more than 50 years. Our Hydro Turbines can be found in Industrial, Municipal, and Agricultural power generation projects around the world. With our wide range of turbines you can generate power with heads as low as 55 feet and flows as low as 90 gallons per minute.

Learn More

Immersible Pumps

The basic design of the immersible pump/motor is a premium efficient, inverter-duty, P-Base or C-Face, totally enclosed, blower-cooled motor. The design prevents water infiltration along the shaft into the motor by utilizing a triple redundant sealing system, including a patented Hydroseal design. The immersible motor can withstand up to 30 feet of submergence depth for a 2 week period.

Learn More

Refrigeration Pumps

Cornell offers both CB-series standard refrigeration pumps with refrigerant emission-free sealing technology, and HT-series hermetic refrigeration pumps. The HT series is perfect for stable operating systems that have minimal vapor entrainment or cavitation issues. The HT series are designed as a drop-in replacement for systems currently using CB-series pumps. Both series offer the advantage of low operating speed, better NPSH, and an industry leading warranty.

Learn More

Solids Handling Pumps

Cornell offers a wide range of solids handling pumps, from 1.25″ though 30″ discharge size, to handle the most difficult solids applications. Cornell’s solids handling pumps can be found in a wide range of applications in the Municipal, Agricultural, and Industrial markets; and available in a variety of mounting configurations including close-coupled, SAE engine, horizontal, and vertical mounted. Featuring enclosed, semi-open, and delta impellers, and a variety of construction materials, Cornell solids handling pumps operate up to 40,000 GPM.

Learn More

Submersible Pumps

Cornell Submersible pumps maintain superb operating efficiencies and are coupled with premium efficient motors. All come standard with heavy wall volutes for extended life under abrasive service. Cornell’s auto-coupling system includes a cast iron discharge elbow, bronze guide claw flange, and Stainless Steel upper and intermediate guide rail brackets for high quality non-spark operation.

Learn More